Bridging the Gap between the Enthusiastic Layman and the Expert.

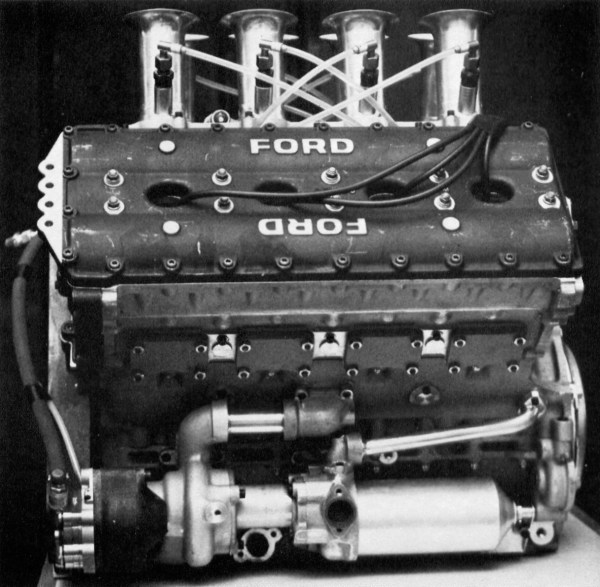

1967 Cosworth DFV V8 Grand Prix engine.

(Ford Motor Company).

Anyone with the slightest interest in motor racing, who witnessed the arrival of the remarkable Cosworth DFV 3 litre V8 racing engine into F1 GP racing in 1967, would not be unduly surprised to see how the essentials of its cylinder head design became a major influence on designers of modern engines over the last 30 years or so. Few, however, would have foreseen that 40 years later production engines would have reduced their output of pollutant emissions to barely 1% of the levels typical of the late 1960s, whilst delivering about 50% better performance, or that the DFV's descendents in 21st century F1 racing would be capable of screaming at 20,000 r.p.m. and producing twice as much specific power.

The impact of the DFV on GP racing can be gauged by the 155 GP wins it racked up between 1967 and 1983 when it was finally ousted by more modern turbocharged alternatives. In fact, turbocharged derivatives of the DFV itself won the Indianapolis 500 race ten times.

Certain features of the DFV have been vital to progress but no more so than all the subsequent advances in electronic engine management techniques, combustion analysis, flow dynamics, surface finishes and test procedures, to mention just a few. Keith Duckworth created the DFV with pencils and paper on a drawing board just as engine designers of 50 years or more before him had done. Nowadays such a project would require a team of engineers with access to vast computing power directly linked to the manufacturing process (CAD/CAM).

So much of modern engine design and development work is dependent on powerful computer systems that enable a designer to explore the effect of slight changes to details like port shapes and cam profiles without ever having to cut metal. One might be forgiven for imagining that almost anyone could design an engine if they had the where-with-all to buy the systems and software, but of course the world isn't really like that.

The combustion chamber is the heart of the engine and has evolved steadily over the years but what was wrong with earlier designs that caused them to be abandoned? What features of a sparking plug really make a difference to the combustion process and what is the connection between modern platinum/iridium electrode construction, WW2 bombers and US President Roosevelt? (See Chapter 1).

In the early 1970s the Wankel rotary engine seemed to be very much in the ascendency but world events wiped out its attraction almost overnight. Multivalve cylinder head designs are now virtually essential to meet modern requirements but what are the features that produce such important advantages over earlier types? (See Chapter 2).

A modern engine management system can be set up to self-program the fueling according to the output from something called a wideband Lambda sensor so why does anyone need to understand anything about it? Well, at some point someone has to determine what the fueling requirement of any particular engine design is at different speeds and loads, during warm up, and also how it might be manipulated in order to control emissions. To be able to do that requires a much more thorough understanding of the subject, but where does anyone find that sort of information?

Another example is how direct injection of the fuel into the cylinder has now become an accepted method for improving emissions, performance and fuel economy, yet the basic principle is hardly new. During WW2 most German aircraft were powered by reliable and well engineered engines of around 33 to 45 litres displacement equipped with direct fuel injection.

It is a surprise then, to find that they were equaled and often outperformed by Rolls-Royce's Merlin of a mere 27 litres breathing through a carburetor. Indeed Rolls-Royce engineers regarded direct injection as something that actually reduced the performance of German engines. It was to keep pace with the Merlin at high altitude that German engineers devised the first nitrous oxide power boosting systems. (See Chapter 3).

Much of the technology is driven by legislation to control vehicle emissions, which most people probably understand the need for, particularly in urban areas. How much difference is there between the emission test that a manufacturer has to satisfy before a new model can be sold and the one that a car owner has to deal with once his car has been out of the showroom for a year or two? How much difference is there between the exhaust emissions of a classic car from the late 1960s and a modern day equivalent that meets the ULEV standard (and what is ULEV)?

A common cause of bewilderment is when a carefully maintained car has failed an emission test or burnt out a catalyst, yet how many other owners breathe a sigh of relief when their pride and joy just scrapes through what they think is a tough test, when in reality they should be wondering why it didn't clear such a simple hurdle with ease. With better knowledge they might approach such times confident of a straightforward pass instead of with trepidation and a desperate dose of ethanol in the fuel tank, but where does anyone find out about the subject? (See Chapter 4).

Most enthusiasts understand the significance of the octane rating of fuels but modern gasoline is vastly different from that which was available 20 years or so ago and continues to evolve to meet the sometimes conflicting demands for lower emissions, better economy, good drivability and extended engine life. How much truth is there in the claims made by fuel manufacturers for their products and what effect do all the additives really have? How does lead resist detonation and how good are the alternatives? Why do some engines suffer valve seat wear with unleaded fuel? How much is octane requirement affected by incremental changes to operating conditions such as air and coolant temperature, ignition timing, compression ratio and so on? Why are alcohols and ethers added to fuels and what effect do they have? What makes a good racing fuel? (See Chapter 5).

Enthusiasts have always enjoyed reading about and talking about ways of increasing the performance of engines but the days of bolting on a couple of big carburetors, opening up the ports in a cylinder head and adding a sports camshaft and a free flow exhaust system are well in the past and probably belong there. The idea that performance is dependent on getting impressive figures by fiddling about with a cylinder head on a flow bench still obsesses many and of course there is no shortage of people wanting to sell traditional go faster bits and pieces, some of which work whilst others might only really have an aesthetic value. There are numerous serious text books and technical papers about modern engine technology but these tend to be written by professionals for professionals, so where does a garage technician, enthusiast or a curious beginner find detailed explanations and information which are not weighed down by mathematical formulas and industry jargon?

The huge benefits from harnessing pulsations in induction and exhaust systems have been obvious for many years and can lift volumetric efficiency well beyond 100%. Clearly the dimensions of passages and pipes are critical but where is there an explanation of exactly what happens, why do some engine configurations work better than others and why is there more to this than just increasing the sizes of pipes? (See chapter 6 and 7).

Induction and exhaust noise can be most appealing to an enthusiast but may be equally offensive to the general public. High performance engines tend to be particularly noisy as a consequence of the enhanced pulse activity but it isn't necessarily the case so how can they be made socially acceptable without too much of penalty? (See Chapter 8).

Camshafts and valve gear are critical to the performance of any engine and involve often conflicting issues with flow dynamics and mechanical forces. Methods for calculating cam lift curves with smooth acceleration abound but explanations about what is really important are not so easy to find. For instance, how is the valve mechanism affected by the firing impulse accelerations acting on the crankshaft and gas loads opposing the initial opening of the exhaust valves and why does the four cam V8 seem to be particularly susceptible to problems with the cam drive? (See Chapter 9).

The potential benefits of being able to vary valve events (timing and/or lift) for optimum performance at different engine speeds have always been obvious yet why are mechanisms to achieve it more likely to be found in the engines of everyday production cars than in high performance and racing engines? (See Chapter 10).

Supercharging and turbocharging are popular and effective ways of getting more performance from smaller engines or, in the case of aircraft engines, for maintaining power at great altitude, yet the engine that first showed the potential was an aircraft engine built for low level racing which set world speed records in the air, on land and on water. Why then did supercharging fall out of favour for many years, with a reputation for heavy fuel consumption, unreliability and disappointing performance, before re-emerging to produce the most powerful and fuel efficient F1 racing engines ever? Obviously there is a lot more to this than just bolting a large air pump onto an engine, yet why is it that the demand for minimal emissions and better fuel economy now motivates manufacturers in this direction? (See Chapter 11).

The purpose of this work is to provide the sort of information that fills the yawning gaps mentioned above. It is not intended for anyone seeking a 'for this problem, do that' guide full of instant cures (an unattainable dream if truth be told), but is aimed at those looking for the knowledge to take them a step up from the glossy go-faster magazines and enthusiasts' forums, or those wanting to develop the understanding and confidence to be able to work things out for themselves, and also those who are looking for a solid foundation before taking up serious study of engine technology.

It is often said that to understand politics it is necessary to understand history. This is also true of many other subjects and some would say that it is impossible to properly understand anything without knowing how it evolved and why. There is much to learn also from the history behind all of the developments along the way and why some ideas didn't work first time but might do in different circumstances and vice versa.

The many hours of research that have gone into this work have been a prolonged learning operation for the writer whose own knowledge and understanding have improved considerably through the process, which has been quite a pleasant surprise.

The text extends to well over 120,000 words and is supported by over 270 illustrations and diagrams. There are no references given because this is a book of general explanations but a bibliography is provided listing works of relevance and recommended reading. A comprehensive glossary and a listing of acronyms are provided to help with unfamiliar terms and expressions.

It might puzzle some to find that an engine that appears quite frequently in the narrative is the Jaguar V12 because at first glance such a complex unit would not seem to be a good example to use. However, it is remarkable in the way it evolved in so many ways so it provides a useful series of yardsticks for comparisons between changes of technology from the early 1960s to the late 1990s. Starting out from complex twin cam prototypes, it evolved into a simpler single cam design for production with combustion chambers in the pistons, an arrangement which was reversed 10 years later to become known as the HE (for High Efficiency). It was first manufactured with carburetors, evolved through an early analogue electronic fuel injection system, then a progression of digital and programmed systems, to end its days with sophisticated engine management. There were a number of 4 valve prototypes (some of which spawned other engines) and of course it won the Le Mans 24 hour race. It is hard to think of any other engine that covered so much ground, but, regardless of that, no V12 engine could ever be accused of lacking charisma.

Roger Bywater.

AJ6 Engineering.

August 2010.

|