|

At this point the Lambda sensing version for use with catalysts added a

further dimension to the control of the final pulse. We saw earlier how the

signal from the Lambda sensor switched between 0.8 volts (rich) down to 0.2

volts (lean) and the duration of the pulse generated by the ECU drifts in

the appropriate direction to correct the error. Note that it is a gradual

correction not an immediate large incremental correction followed by

smaller increments typical of later systems. There is no stable mid-point -

the fueling is always undergoing correction either rich or lean.

Being fundamentally an analogue device the ECU cannot be programmed to

suit the engine as would a more modern one. A laborious sequence of engine

tests has to be undertaken to measure the fuel requirements over a range of

conditions. At each condition a graph called a fuel loop is generated

showing the effect of incremental changes from rich to weak limits. From

this data the airflow meter and ECU are calibrated to obtain the best match

to the specification. This is then refined during road, performance and

emission tests to arrive at a standard which is acceptable with all the

variables resulting from build tolerances, etc. This is not the work of 5

minutes, however, the limitations of the system forces compromises which

modern programmed devices could easily overcome. Despite this L Jetronic

represented a major advance over carburetters.

In the midst of all the calibration work an error nearly occurred due to a

misunderstanding in the interpretation of data. The exact reason is rather

complicated to explain in detail but would have caused a richer than

intended fueling specification. It was spotted just in time by a rather

bright Senior Emissions Engineer called Albert Baxendale who produced a

cleverly worded memo to explain how the discrepancy had arisen.

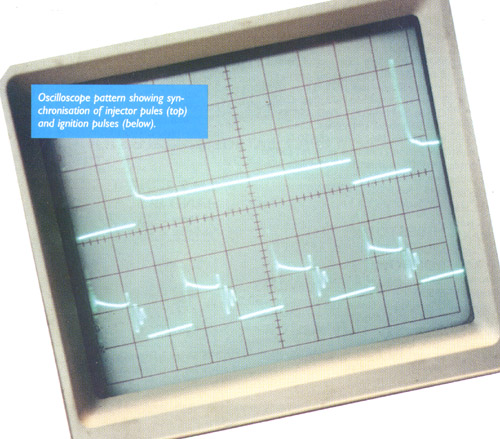

The final pulse is used to drive a pair of hefty output transistors which,

by providing a current path to ground, switch the solenoid injectors on and

off accordingly (see photo). A pack of power resistors each of

approximately 6 ohms is interposed between the individual injectors and the

transistors with the dual purpose of limiting the current through each

injector to about 1.5 amps and isolating any short circuit whilst

protecting the transistors in that event. Note that the two output

transistors operate simultaneously as do all 6 injectors.

|

FAULT DIAGNOSIS - the basics

- Fuel pressure is specified as 2.5 bar (36 p.s.i.) without vacuum applied

but with the engine running this will fall in proportion to the prevailing

manifold vacuum. If in any doubt at all it is always good practice to check

fuel pressure with a gauge, if possible with the engine running and at full

power, at an early stage when trying to diagnose a problem.

- Fuel tank change-over valves are a notorious cause of trouble. The worst

offenders are located behind panels in the back of each rear wheel arch and

when they fail the usual result is fuel becoming transferred from one tank

to the other, possibly overflowing if more than half full, as the return

feed becomes misdirected. Jaguar issued a bulletin in 1979 advising that if

the left hand tank were used before the right hand one after fill up the

problem would be less likely to occur.

- Early cars used a double relay to control power switching into the

system but after some reliability problems separate main and fuel pump

relays were adopted. A failed relay will obviously deprive the relevant

circuit of power and is easily identified.

- Terminal numbers of components are allocated logically so that, for

example, terminal 7 on the airflow meter connects to terminal 7 at the ECU.

- L Jetronic ECUs seldom give trouble and when the system goes wrong the

airflow meter is far more likely to be the culprit. The earlier section

about the airflow meter gives guidance on the matter.

- Do not forget to check the crash protection inertia switch located next

to the left hand front door hinge (A post) if the system has become

immobilised.

- A group of ground leads from the EFI system are fastened at an inlet

manifold bolt towards the back of the engine. These leads seem to be

vulnerable to strain during major repair work and if any become open

circuit this could immobilise the car.

- If the injection system does not seem to be triggering first ensure

that the ignition system is working properly - without sparks there will be

no trigger signal to the EFI system.

- Backfires in the intake usually indicate lack of fuel. Bangs in the

exhaust point to an ignition problem.

- Injectors rarely fail electrically but do sometimes become deposit

fouled with age causing vague symptoms of weak fueling and erratic running.

Ultrasonic cleaning usually cures this.

- If the injector power resistor pack becomes faulty it is unlikely to

afflict more than one injector, however if the connector suffers corrosion

or the terminal contacts become insecure more injectors could be affected.

- Lambda sensors on emission cars do not last for ever but their action

(steady oscillation between 0.2-0.8 volts) can be checked at the back of

the ECU connector with a high impedance voltmeter, but because these cars

have idle enrichment the throttle must be opened slightly to give about

1500 revs. The ground connection to the Lambda screen lead must be intact.

- An open circuit coolant sensor will cause very excessively rich

fueling and whilst the engine will probably start from cold it will swamp

out and die after several minutes running.

- The air intake from the filter housing projects forward alongside the

radiator and has a moulded bell-mouth to smooth air entry. If this becomes

detached, quite easy whilst changing a filter, there will be a noticeable

loss of power. It is no embellishment - it needs to be in place.

- An engine that just seems a bit rich everywhere may have a faulty full

load switch or the vacuum pipe to the switch may be detached (Euro

versions).

- Any air leak downstream of the airflow meter will cause weak fueling

to some extent.

- An engine which just cycles up and down around 1500 revs when the

throttle is opened is likely to be running in over-run cut off. Check the

throttle switch. Because the micro-switch is quite audible it is simple to

adjust so that the "click" occurs as the throttle just begins to open,

however, these switches do sometimes fall apart.

- The cold start injector only fires briefly during cranking to aid

initial fire up. Without it the engine will just take a couple of seconds

longer to start from cold. Don't waste time on it or its thermotime switch

when faced with any other problem.

- Idle mixture on European cars is specified as giving 1-2 % CO but

these elderly engines seem rather happier at 2-3 %.

- A wandering idle speed may be due to the over-run valve leaking as the

spring sags with age. Raising the spring tension by a couple of turns on

its screw will usually effect a cure.

|