| Menu |

| Homepage |

| NEW & REVISED BOOK! |

| Personal intro |

| Philosophy |

| Intro technics |

| FAQ |

| Exhaust systems |

| Exhaust overview |

| E-type |

| XJ Saloon S1,2,3 |

| XJ40 (AJ6&V12)/X300 |

| XJS |

| XK8/XJ8 |

| TT exhaust explained |

| The Jaguar V12 |

| V12 Performance |

| E-type EFI conversion |

| D Jetronic |

| Lucas EFI |

| Vacuum advance |

| Ignition systems |

| V12 throttle linkage |

| Article: V12 Engine |

| V12 Archives |

| The Jaguar AJ6 |

| AJ6 Performance |

| 3.6 Richness |

| AJ6 fault codes |

| AJ6 Archives |

| The Jaguar XK |

| XK Performance |

| Article: XK Engine |

| Article: 4.2 EFI |

| The Jaguar V8 |

| V8 Performance |

| AJ6 Superchargers |

| Superchargers |

| Supercharging article |

| Suspension & Brakes |

| ECU repairs |

| Miscellaneous bits |

| Glossary |

| Prices & ordering |

aj6engineering@ntlworld.com

Updated August 2016

Visitors:

73348885

|

|

STRETCHING THE V12

The following is a list of known bore and stroke dimensions used or seriously proposed that have gone beyond paper speculation.

BORE SIZES:-

STROKE VARIANTS:-

Not including every possible combination capacities range from 5.0, 5.3, 5.7, 6.0, 6.1, 6.3, 6.4, 6.8, 7.0, 7.3, 7.8, 8.1, 8.3, 8.4, and 10.058 litres!

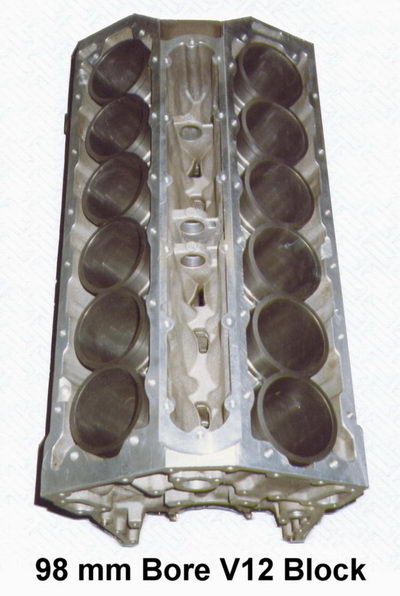

The photo shows an example of the 98 mm bore block conversion which we jointly devised with Ron Beaty. It will accommodate 2" inlet valves and 1.75" exhausts - in a pre-HE flat head of course.

Original twin cam prototypes (XJ13 etc.) 87.0 mm Standard 90.0 mm TWR racing - aluminium liners 92.0 mm Overbore - standard liners & gaskets 93.5 mm TWR racing - aluminium liners 94.0 mm Overbore - special liners & gaskets 96.0 mm Overbore - special liners, gaskets, bore centres moved 98.0 mm Maximum known overbore - ditto. 98.5 mm

Standard forged crank 70.0 mm Welded standard crank, forged or billet crank 78.0 mm XJR-S forged crank 78.5 mm Production 6 litre forged crank 78.5 mm Production 6 litre cast iron crank 78.5 mm Forged or billet crank 84.0 mm Billet crank, sandwich plate on block 90.0 mm Billet crank, sandwich plate on block 92.0 mm Billet crank, 3" spacers on modified block, longer conrods. 110.0 mm

To estimate the potential performance a torque figure of 65 - 70 lbs per litre will be somewhere near for a well developed road tune engine and about 65 - 75 b.h.p. per litre in the smaller sizes falling back to 60 - 70 b.h.p. per litre at the larger sizes, other than the 10 litre which is a relatively low speed engine intended as an aircraft power unit.

For a full race tuned engine about 90 - 95 lbs of torque per litre and 90 - 105 b.h.p. per litre, the power falling off a little in the larger sizes, would be realistic targets without vast funding.

Because of the small and pocketed exhaust valves HE heads restrict the power of the larger sizes although low to mid-range torque rises more or less in proportion with size.

4 VALVE HEADS ON THE V12.

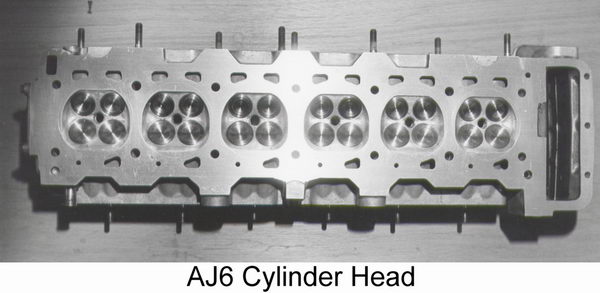

Hardly a month goes by without someone telling us they have this great idea of adapting AJ6 cylinder heads to create a 4 valve version of the V12. The thinking goes that as both engines have the same bore centres and main stud spacing the heads must easily interchange. The need for a left hand head is solved by just cutting the timing cover off one head and welding it on to the other end. Suitable pistons can be found just by searching through a few catalogues so it cannot be all that difficult to finish the job, surely?

Sadly, it isn't that simple. We first recognised the potential back in 1985 but have seen nothing since to change the view that we formed then that whilst it would be possible, it would not be worth the effort and certainly would not be commercially viable.

The question to ask is not "can the AJ6 head be made to fit?" but more importantly "if we were to start with a clean sheet of paper would we end up with something similar?" to which I have always believed the answer is "NO". The reasons against using the AJ6 heads on the V12 far outweigh the convenience of a few shared dimensions. Let me explain:-

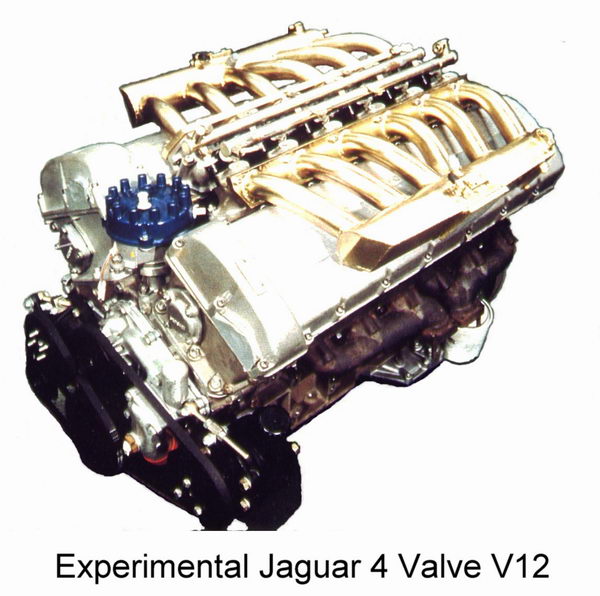

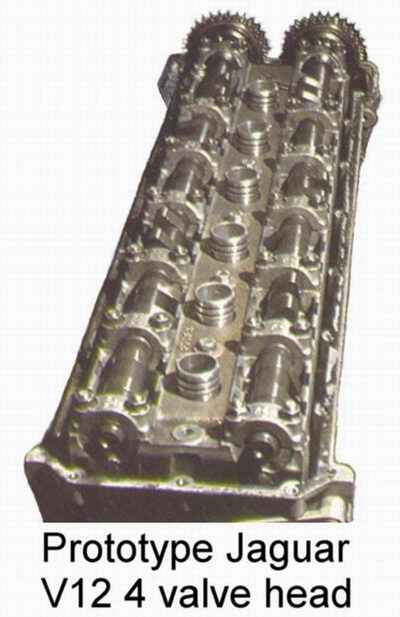

Jaguar produced some prototype 4 valve V12s in the early 1970s. A fast road tune version produced about 400 b.h.p. and a race tune version 627 b.h.p. which was quite impressive for the time, but has since been matched and often exceeded by well developed 2 valve engines. Jaguar never proceeded with the 4 valve V12 because the market simply did not warrant the extra complication although one of these engines was updated to grace the engine bay of the prototype XJ220. There were a number of slant six engine spin-offs, basically one half of the four valve V12, running experimentally all through the 1970s. The knowledge gained did contribute to the AJ6 program although that actually started out on a derivative of the XK block.

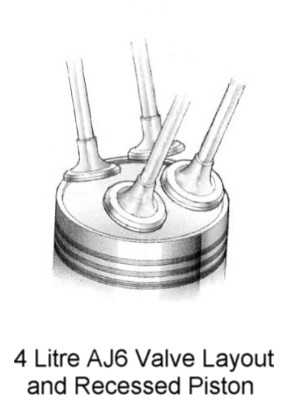

The AJ6 4 valve head was introduced to suit a cylinder size of 598 ccs. (3.6), later going to 663 ccs. (4.0) with also a more compromised downsize to 539 ccs. (3.2). According to the usual yardstick of b.m.e.p. the 4 litre must be considered the optimum variant which indicates that the porting and valve area well suits that size of cylinder. The 4 litre cylinder is approximately 50% bigger than the 445 ccs of the 5.3 V12 so the AJ6 head is a long way from being ideal for that engine. This also applies to the compression ratio and would necessitate a substantial hump on the piston crown. Now one of the features of good four valve cylinder heads is that they exploit barrel swirl, a condition where the incoming charge rotates around a horizontal axis. After ignition the flame front is therefore swept past the hot exhaust valves first, considerably reducing their potential to promote detonation, then this controlled swirl degenerates into general turbulence spreading the flame all around the chamber. For that reason the pistons of four valve engines benefit from being flat or even slightly recessed, as the 4 litre AJ6, and a significantly humped piston is undesirable because it would interfere with the swirl/turbulence conditions.

One might therefore consider making the engine bigger, but really it needs to be around 8 litres to suit the AJ6 head. But is it not obvious that an 8 litre V12 with a simple 2 valve head would be capable of producing more than enough torque and power for almost any application that could be envisaged?

Then there is the matter of the angle between the valves, technically known as "valve included angle". For the best compromise of valve size, compression ratio and burn properties, designers would usually aim for an angle of around 30 degrees on four valve engines, however this results in the camshafts and head bolts fighting for the same space so a wider angle of around 45 degrees is often used for production engines of roughly square bore/stroke proportions. This permits the head to be treated as a complete bolt-on assembly.

F1 racing engines, on the other hand, evolved to having a smaller valve angle, of maybe 20 degrees or less, in order to maintain a compression ratio of near 13:1, with ever increasing bore/stroke ratios. Recently F1 engine designers have had to forsake the classic pentroof type of chamber to achieve the conflicting needs of biggest possible valve area and compact chamber volume on top of a bore/stroke ratio around 2.5:1 - i.e. about 98 mm bore x 40 mm stroke! Pairs of valves are no longer parallel, they are splayed outwards by a few degrees and the chamber surface sweeps up to form slight ridges between the valves, permitting the spark plug gap to be located more prominently.

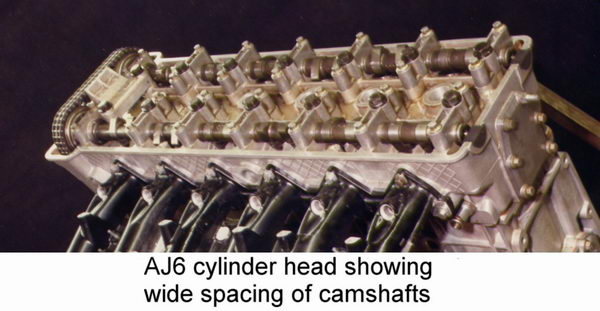

A feature of the AJ6 engine is that the camshafts lie outside the head bolts, which pass through the camshaft bearing caps. This results in a valve angle of 47 degrees so it is a relatively wide angle design, wider than some 2 valve hemi-heads, but notably the Coventry Climax flat-16 GP engine created by much the same design team 16 years or so before, was almost the same at 48 degrees. Jaguar's later V8 has a tighter valve angle of 28 degrees so clearly the extra complication of having the head bolts under the camshafts is now considered worthwhile in pursuit of the ideal combustion chamber geometry and, of course, compactness.

Jaguar's original 4 valve experimental V12s used a valve angle of around 30 degrees as did the later TWR versions. The latter were certainly powerful but the extra weight high on the engine adversely affected handling and the power could not be used without excessive fuel consumption so the type was abandoned after just one race. These TWR 4 valve heads, like Jaguar's, were much lighter and more compact than the AJ6 type - narrower by about 2" at the timing end and by about 1.25" along the main length.

The construction of the two types was markedly different with alternative approaches to the camshaft/head-bolt conflict that reflected progress over the years. The Jaguar 4 valve heads were designed according to what was almost standard practice at the time, typified by the Cosworth DFV, of having a separate carrier for the camshafts and tappets, bolted on after the head was tightened down. By the time the TWR version was conceived ingenuity and improved casting techniques had made it usual for heads to be constructed in one piece. As has now become normal practice the TWR team placed the cam bearings between the pairs of valves where they are better able to resist camshaft flexure - an arrangement also found on Jaguar's more recent AJ-V8 power unit - the head bolts being accessible by removing the camshafts.

TWR later produced a one-off road version with smaller ports and valves and mild cams. It had curved-over cast inlet manifolds reminiscent of the standard V12 and even used the production throttle castings (presumably bored out) and linkage. It displaced 6.4 litres and produced 475 b.h.p. at 6000 and 470 lbs of torque at 4500 and was installed in an uprated DB7 used for a time as personal transport by Tom Walkinshaw.

In truth a larger two valve flat-head V12 could have done the same job better and much more easily.

Then there is the structural integrity of the engine to consider. The V12 open deck cylinder block is heavily dependent on having the heads attached in order to achieve adequate torsional stiffness. On the other hand the block of the AJ6 engine was intended to allow for a possible diesel variant so was designed from the outset to be extremely robust. Putting what was essentially a V12 HE head on the stiff AJ6 block, as Jaguar did to create the 2.9, is relatively simple. Trying to do the reverse, putting a head designed for a stiff block onto one that isn't, could invite trouble.

An associated complication is that the V12 cylinder liners are designed to stand 0.005" above the block face to ensure correct "nip" on the gasket for gas sealing. Supplementary studs around the outer water jacket give additional rigidity to the structure and seal the coolant joint. The same arrangement was used with Jaguar's prototype 4 valve heads and the later ones designed by TWR. It is difficult to see any way of accommodating these outer studs with the AJ6 head, designed as it was for its own rigid decked block.

Probably the only way of achieving adequate rigidity without the outer studs is to weld a deck structure to the block which would entail converting to slip fit, dry liners inside aluminium sleeves. This of course is how the original twin cam hemi V12 prototypes were constructed.

Then there is the provision of a reliable camshaft drive. The single chain arrangement of the standard V12 is not at all practical in this context because of the torque fluctuations that can arise in a twin cam four valve layout. In fact the two stage timing drive of the AJ6 engine was never totally free of problems and Jaguar's later V8 has acquired a reputation for trouble in this area. A simple chain drive to each bank might work in the short term, but a two stage drive is probably necessary to achieve reliability. Certainly that was the conclusion reached by Jaguar, TWR and KRS (see below). Some very respected engineers have suffered a lot of frustration trying to solve unexpected problems with camshaft drives. There is a saying "all camshaft drives can work and all camshaft drives can fail". At least the difficulty of accommodating a distributor drive can be resolved by use of a modern coil-on-plug engine management system.

Having worked out how to get the basic engine together it becomes necessary to consider the other details like coolant passages, purpose made induction and exhaust systems, timing registers and so on. Some ingenuity will be required to make everything fit in the same engine bay space without too much compromise. When it is all together there is the matter of setting up and mapping fuel and ignition, requiring many hours of laborious dynamometer work.

Realistically it would need a sizable budget to do the whole job properly as TWR apparently did. Of course a one-off could be put together at moderate cost as a spare time project for somebody but one-offs prove nothing and as it has all been done before what would be the point? I don't see any sense in doing something that is both difficult and compromised by circumstances when a much simpler alternative is so obviously available.

Just stretching the standard V12 to 8 litres or so would be simplicity itself by comparison - for a fraction of the effort and cost, though still not cheap - and would be lighter, less bulky and altogether more satisfactory.

An article about a V12 E type with AJ6 heads was published in Jaguar World, March/April 1993. It was a 6.8 litre unit produced by Sovereign Motors in California who offered similar engines for sale at a mere $45,000 each - a price which puts the scale of the job into some sort of perspective. It all looked very neat and tidy but the induction ram length appeared far too short to be effective. Apparently Sovereign Motors are no longer in business so it doesn't seem to have been much of a success.

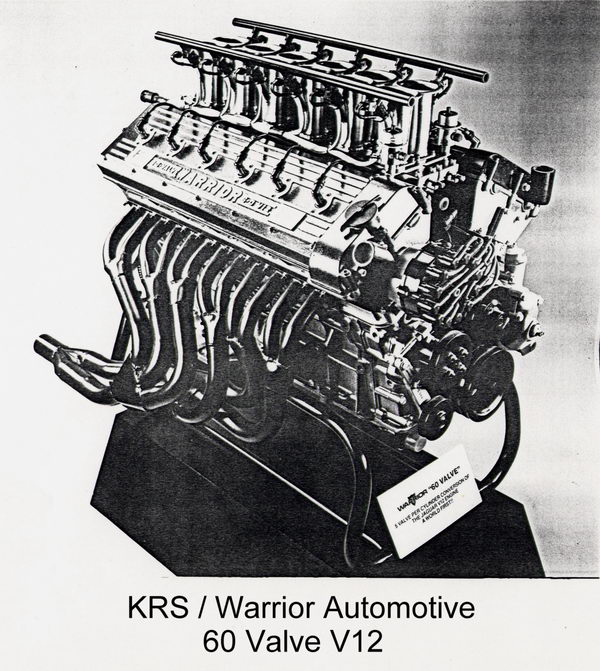

In the UK a company called Warrior Automotive, a subsidiary of machine tool manufacturer Kearns Richards, publicly displayed a 60 valve conversion (5 valves per cylinder) for the V12 back in about 1988. This apparently drove the cams via gears from an idler driven by chain from the crank. There doesn't seem to be any evidence that it ever actually ran under its own power and the entire KR group went bust with the loss of about 400 jobs not long after. A few years earlier I had been technical director of the automotive branch KRS so I was not without some insight into the situation.

Email aj6engineering@ntlworld.com, Tel/Fax:- 0044 (0)1625 573556